UNDERSTANDING IONIZING RADIATION Introduction In the realm of physics and radiology, ionizing radiation stands as a pivotal concept, both for its utility in various fields and its potential risks. This article aims to demystify ionizing radiation, exploring its nature, sources, applications, and the necessary safety measures associated with its use. What is Ionizing Radiation? Ionizing […]

UNDERSTANDING RADIATION RADIOACTIVITY & IONIZING RADIATION Introduction All too often all that people know about radiation is its connection to the atom bomb and its massive destructive powers. The terms Radiation, Radioactivity, and Radioactive are often times used interchangeably, while not always technically correct. Further confounding this issue is another less-known term called Ionizing Radiation. […]

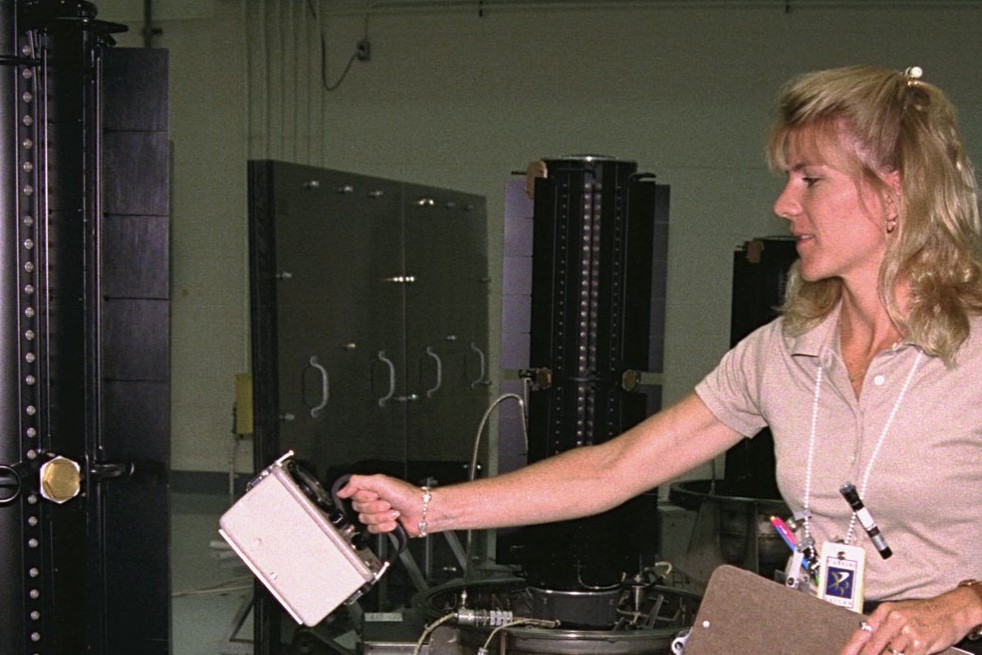

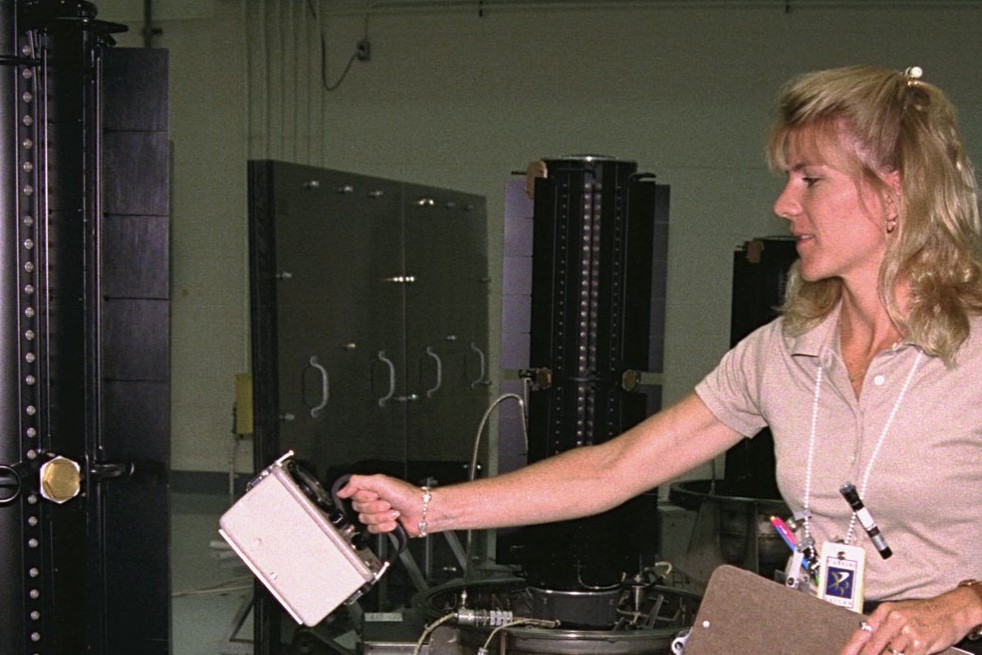

What are the Area Radiation Survey and Radiation Survey Meter Requirements for Fixed Gauges? Why are Area Radiation Surveys Required? All licensees are required to have radiation area surveys conducted anywhere there is a radiation device or the potential for receiving a dose greater than what is allowed. The regulation citing is found in 10 […]

What’s the Difference Between Routine and Non-Routine Maintenance for Fixed Nuclear Gauges? Introduction Today’s Radiation Safety Officer (RSO) face increasing pressure to lower operating costs in order to remain profitable and competitive in their respective industries. Maintenance is typically a major budget item that comes under scrutiny and careful inspection to see where cost cuts […]

Radioactive Consumer Products Radioactive Consumer Products Around Us Most people are unaware of the fact that there are several radioactive consumer products in existence. Radioactive materials ability to radiate its rays flawlessly over many years without an external power source has attracted manufactures to utilize them. Other times they are utilized for their illumination properties. […]

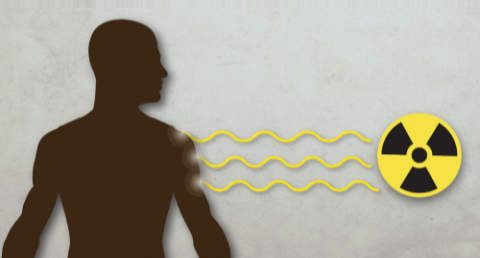

Remembering the Harmful Effects of Ionizing Radiation Introduction Scientists have known for a very long time now that exposure to ionizing radiation can have harmful effects in humans. Awareness first manifested itself by radiation burns on the early experimenters who paid dearly for their work. Fortunately, modern radioactive devices employ many well engineered safety measures […]

Relating Radiation Measurement Units to Water If I were attempting to explain radiation measurement units to something even a child could understand, I would liken it to water which I feel really works well as a metaphor. In many ways one can draw simple analogies using water to relate it to radiation. After completing my […]

What is Radiation? To many, the term radiation is a confusing and even a terrifying subject, but it need not be so. Like any other subject, once its better understood, it’s not as mysterious or frightening. The purpose of this article is to present this subject as simply as possible by avoiding nuclear physics, mathematical […]

We Load Irradiators Too! Some Job Examples Another successful unload/reload of several J.L. Shepherd irradiators. We provide service to most J.L.S., Nordian and IBL irradiators. Contact us for all your irradiator service needs.

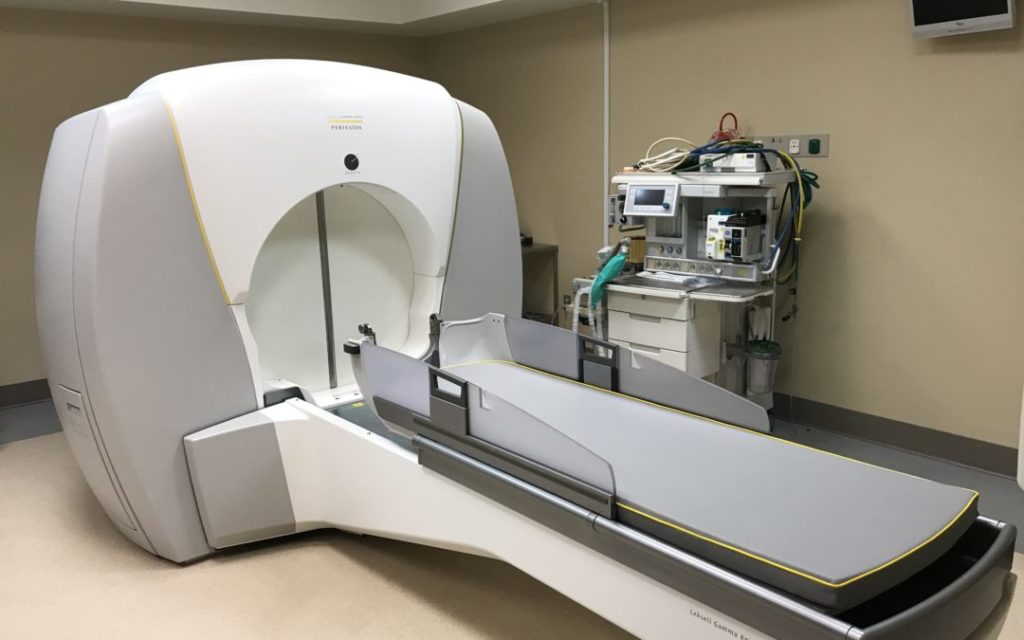

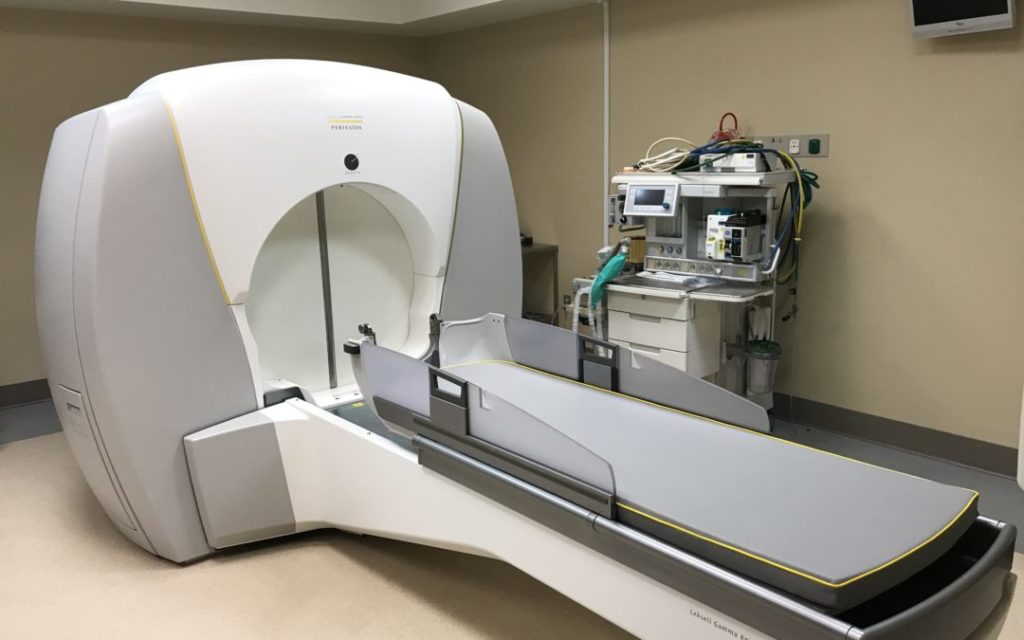

Gamma Knife Source Removal/Disposal Gamma Knife Job Another successful Gamma Knife source removal/disposal. We can unload any Gamma Knife. Call us for an estimate. Learn more about our disposal services